The 2026 season marks the greatest technical revolution in the history of Formula 1, at least since my career began in 1969. For the first time, teams have been forced to truly start from scratch, without any established datas. Everything is changing: smaller car dimensions, aerodynamic rules, power units, tyres that are also reduced in size, active aerodynamics both at the rear and the front, a 30-kg weight reduction, and greater freedom in braking systems.

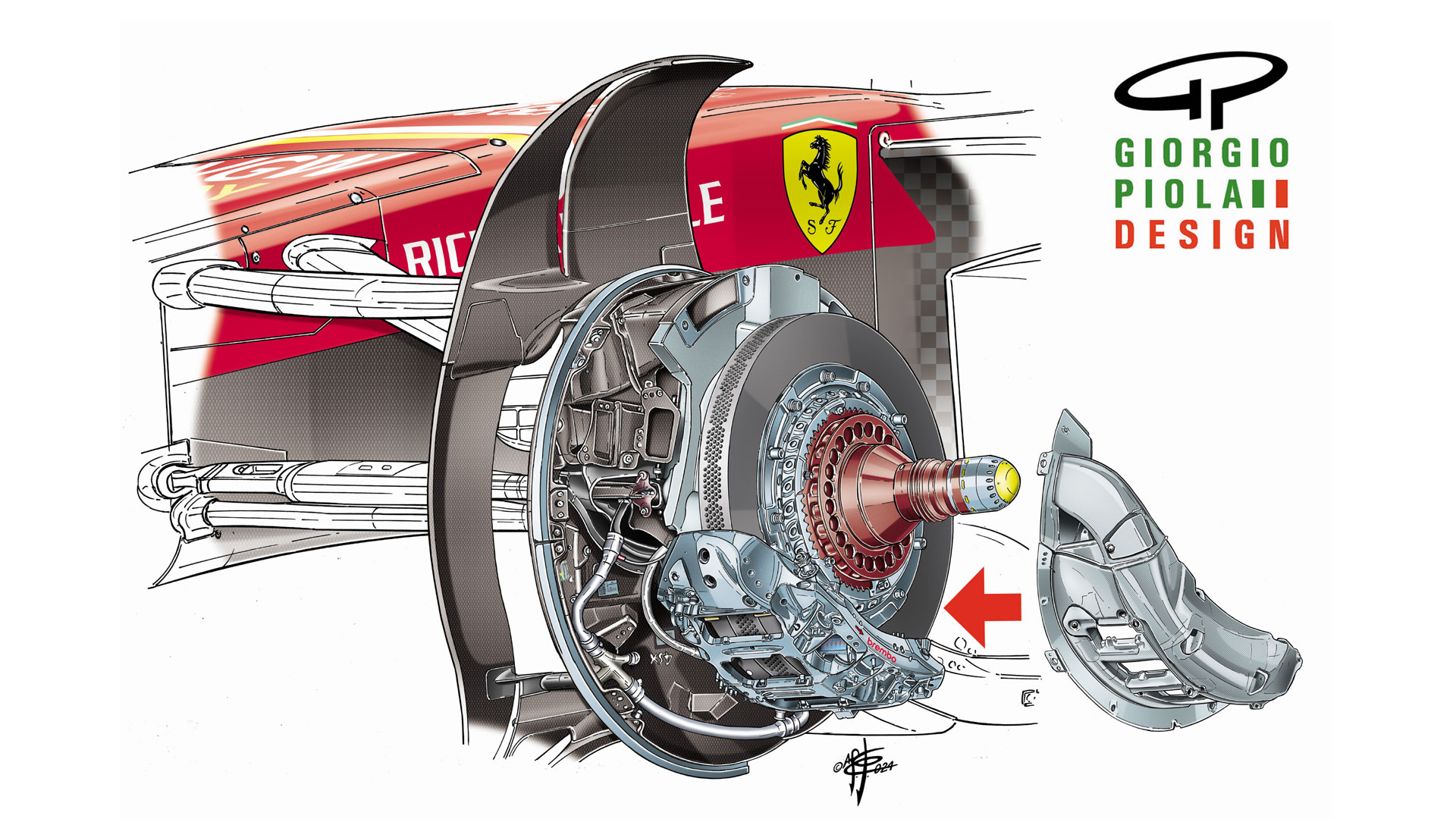

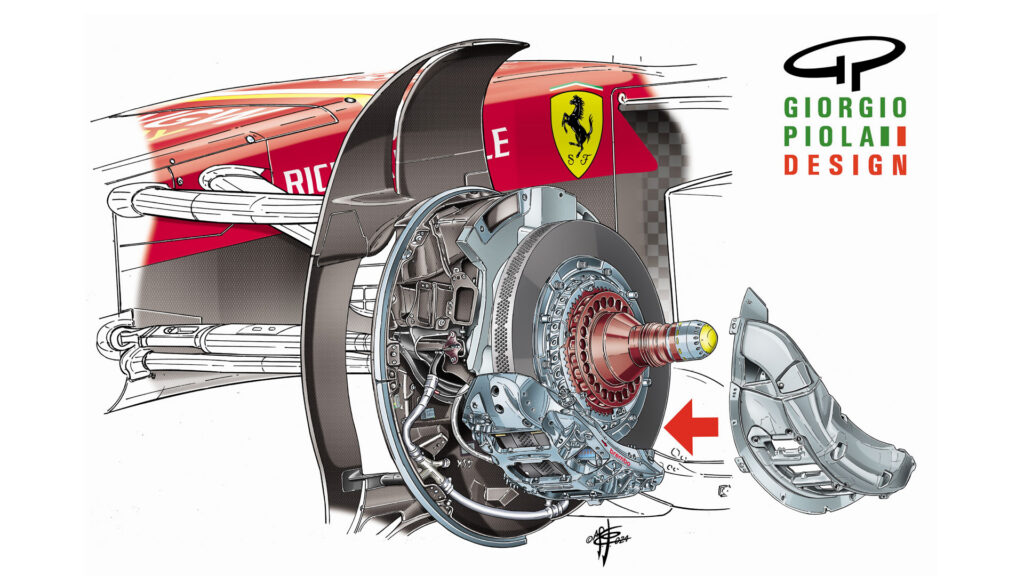

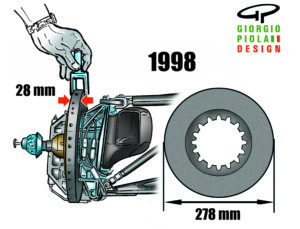

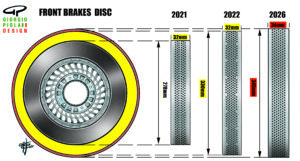

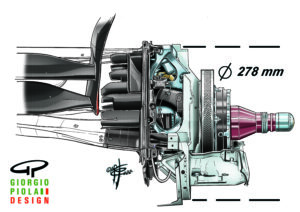

The brake sector had been stuck with heavy constraints since 1998 in terms of diameter (278 mm), disc thickness (28 mm), number of pistons (6) and caliper mounting points (2). In 2026, this will change to 3 points to ensure greater rigidity.

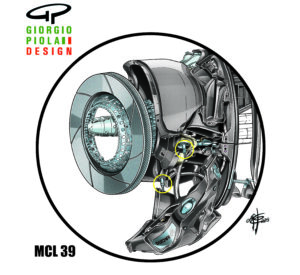

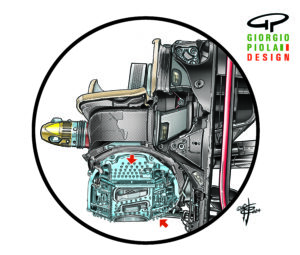

This last area, in particular, had remained largely frozen for almost thirty years, from 1998 to today. The braking sector has also become increasingly complex to interpret and observe, partly due to the sophisticated shrouds that conceal most of the components. Suffice it to say that it was only at the final race of the season that it emerged that McLaren had been using A+P calipers (Brembo Group), because only in Abu Dhabi did the mechanics open the complez drums all the way to the calipers shortly before FP1.

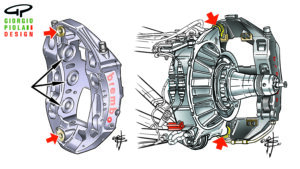

Only in Abu Dhabi was the A+P supply for McLaren calipers and ‘baffled’ discs discovered.

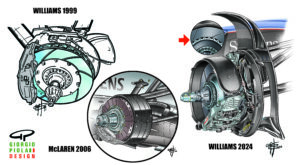

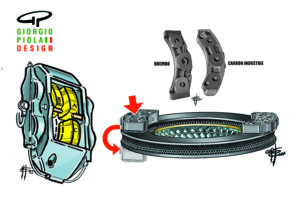

“Buffed” brake discs were seen in 2024 on Williams and Alpine, and this year on McLaren. This solution was popular with metal discs but was only rarely paired with carbon in 2005 and then abandoned after 2006. Not coincidentally, McLaren used exclusive Mitsubishi “buffed” discs together with exclusive Akebono brake calipers.

The ‘baffled’ discs, standard in the days of metal discs, were seen on carbon discs on the McLaren in 2005/06.

It should therefore come as no surprise that, under the new regulations, technical solutions from the past—previously blocked by the existing rules—will make a comeback in 2026, reinterpreted in light of the greater freedom.

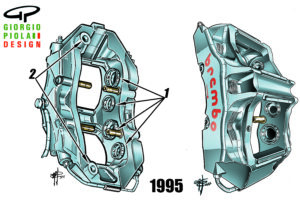

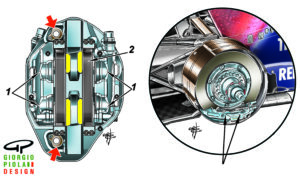

Let’s now delve into the details of the 2026 rules. The maximum limit of six pistons per caliper disappears: calipers will no longer be restricted to two pads, and a four-pad configuration will also be allowed. Eight-piston calipers will therefore return—a solution Brembo developed at the end of 1995, which I had the opportunity to quickly sketch at the time (I was then the only technical designer consistently present at the Grands Prix)—and which I have now redesigned more accurately.

With the maximum limit on the number (6) of pistons for brake calipers abolished, the 8-piston caliper introduced by Brembo in 1995 (sketch from that period) may make a comeback. On the right is a more accurate reconstruction made in 2022.

The limit of two pads per disc has also been abolished, and in the 2026 season it will again be possible to use up to four pads per disc. It is worth noting the significant and sophisticated reduction in the weight of pads in recent years, with further developments for new solutions.

The innovations in the braking sector represent one of the central themes of my opening review of the 2026 season. This is a department that must necessarily contend with the significant reduction in car weight—30 kg less. This constraint has had a profound impact on the teams’ design choices, including the integration of braking systems, which are called upon to balance almost opposing requirements: on one hand, torsional stiffness and braking efficiency, and on the other, the reduction of unsprung mass, which is far more advantageous than an equivalent reduction in sprung mass.

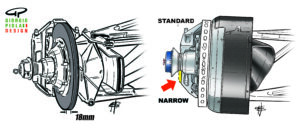

For decades, the braking sector has been a key part of my technical reports from the circuits and my “Tecnical Analysis” season books, published before the Covid period. In the past, there were three disc suppliers—C.I., Hitco, and Mitsubishi—and three caliper suppliers—Brembo, AP, and Akebono (the latter exclusive to McLaren)—with a particularly wide variety of technical solutions evident on the most demanding tracks such as Montréal and Monza. Not to mention the era of qualifying cars: in 1991, for example, Ferrari even tested solid discs with a thickness of just 18 mm, and there were also qualifying or “light” calipers.

In the 1990s, there were lighter and more extreme single-seater qualifying cars with lighter calipers. At Monza in 1991, Ferrari tested solid discs that were only 18 mm thick.

An immense challenge for Brembo, which holds the exclusive supply of calipers for all teams, each with obviously new layouts, all different from one another and developed in close collaboration with the teams.

To delve into the technical details of this revolution, I turned to Brembo’s track technical manager in Abu Dhabi, Eng. Andrea Algeri.

“The novelties allowed by the regulations are: an increase in the number of caliper mounting points, from 2 to 3, the number of pistons, which rises from 6 to a maximum of 8, and the number of pads, which can reach up to 2 pairs, i.e., 4 pads per caliper. On the disc side, the diameter changes, reaching up to 345 mm maximum, and the thickness up to 34 mm, compared to the current 330 mm diameter and 32 mm thickness. It should be noted that until now, most front discs had a diameter of 328 mm to slightly reduce the weight and the size of the corner.

In addition, there are changes to the minimum hole diameter, which drops to 2.5 mm, before 3mm. Therefore, with smaller holes and increased thickness, it will be possible to reach over 1,400 holes per front disc, as we had a few years ago. This type of disc sizing was initially done because early simulations indicated a significant increase in energy and also essentially the need to cool the system. In reality, however, during various tests, including on team benches, it became clear that the situation at the front will not be too different from this year, so the teams are not using all the freedoms allowed by the regulations and will therefore go with systems fairly similar in size to this year.

Then, of course, they will take advantage of the new possibilities on the calipers: increasing pistons, increasing mounting points.”

The diameter of the brake discs (278 mm) remained unchanged from 1998 until the introduction of 18″ rims in 2022, when it increased to 330 mm, while the thickness remained unchanged (32 mm). For the 2026 season, the diameter will become 345 mm and the thickness 34 mm. The rear discs are very small, even beyond the 278 mm limit, especially considering the size of the rims (18″).

Will the trend of 4-piston calipers remain at the rear?

“Yes, let’s say the regulations set the maximum, not the minimum. So, a four-piston caliper with disc dimensions very similar to this year’s—280 mm, but increased to 34 mm in thickness. The focus will be on a very small, very light system because the rear will be heavily influenced by the energy recovery, which will increase, and so everyone will try to make the system as compact as possible. The real challenge is that, for most of the time, the rear system will hardly be used. However, there will be situations where, with a fully charged battery or when energy recovery is not possible, the brake will actually have to do the work it used to do in the past. So we expect a big difference between standard conditions and maximum conditions. Obviously, the brake is sized to withstand the maximum torque it will experience. The trick is to make it function correctly even when most of the braking energy is being absorbed by the engine. The challenge is to have a material ready even when cold, with a wide temperature range, to provide the correct performance.”

In the 2009 season, Red Bull used a 4-piston caliper. This solution became widespread in 2014 with the introduction of KERS. Note the two attachment points to the hub carrier and the use of only two pads in the design of the 4-piston caliper.

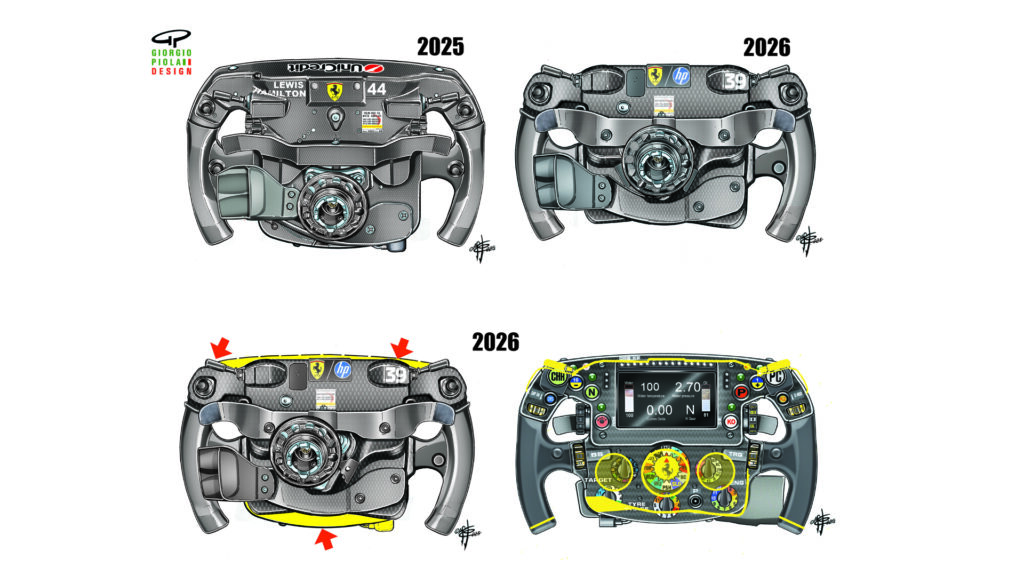

Will the driver need to adjust the brake balance more, or will it remain almost the same as now?

“I believe there will be additional challenges for the driver. Beyond the brake balance, there is the more complex management of energy recovery, which influences the brakes. Brake balance will be one of the paddles the driver can use to achieve maximum performance, but there will also be recovery strategies that affect lap time and, consequently, the car’s braking behavior.”

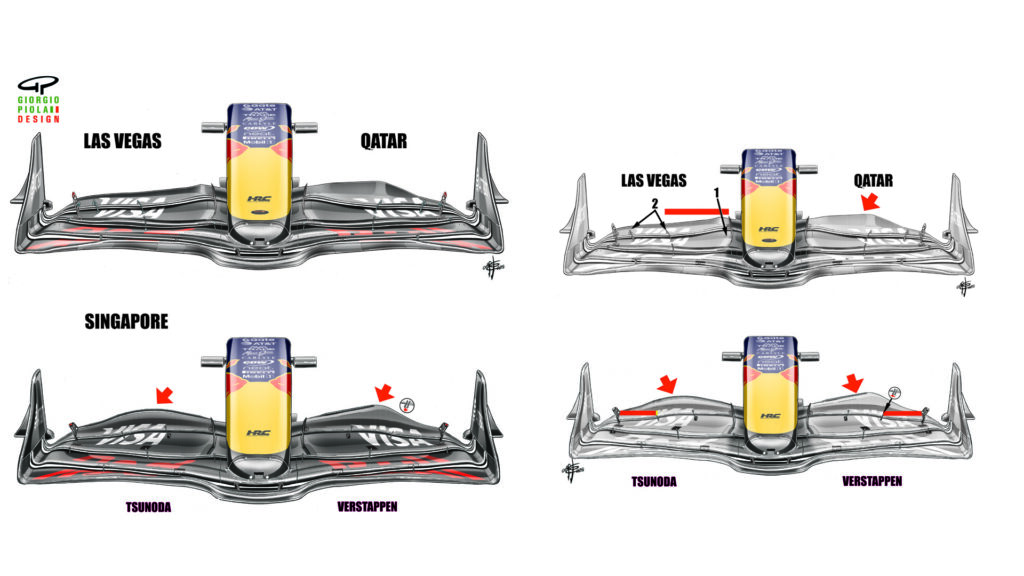

Will there be many differences from team to team, or is there more or less a similar approach?

“At the front, more or less, the systems will be similar, with the main differences being on the caliper side, which is what the teams have been allowed to explore the most. At the rear, however, there are quite a few differences: thickness, disc diameter, and consequently the caliper design, which obviously must match the rear disc dimensions.

We’ve seen fairly different design approaches—some with more extreme choices, others a bit more conservative. We’ll see who gets it right; there could even be developments during the year, already in the first season, if someone has made a mistake one way or another. Those who have pushed the extremes and cannot achieve the correct performance or the proper lifespan of discs and pads during use will be forced to change their design. Others, who may have ended up with a heavier, more conservative solution, can act immediately or wait until the following season to optimize their package.”

At the rear, there could be differences in thickness and diameter. Is there a minimum for thickness and diameter, or only a maximum limit?

“The disc dimensions are expressed as maximum values, but the regulations also specify a torque limit that the disc must somehow withstand at a certain pressure. Assuming a certain friction between disc and pad, this is something the team must demonstrate through a bench test, which can be done internally or by a supplier. Once this bench test is completed, the team must guarantee that the rear corner reaches a certain torque value, to avoid very extreme designs or discs that might be fragile under particular operating conditions. The regulations set this torque, and the team must, in some way, prove that their system complies with the specifications requested by the rules.”

At the rear, the trend will be towards 4-piston calipers and disc diameters even smaller than the maximum permitted (278 mm). The same applies to thickness, which may be less than 34 mm.

Could there be any innovations in materials?

“We are starting with materials very similar to 2025, so we have a couple of options for pads and also a couple of options for discs. Of course, Brembo will also need to understand whether the type of stress and performance required from the rear disc fully aligns with the characteristics of our material. At the moment, it seems that, by working with modifications to geometry, pad surface, band height, and braking surface height, we can manage quite well with the cycles provided by the teams and with the simulations.

Once the cars are on track, we’ll see if it will be necessary to work on the material as well. Carbon fiber has operational limits that are fairly well defined in terms of temperature, and we need to understand the conditions we will encounter and whether the material behaves as expected. If not, we will have to work on the material itself, not just the geometry.”

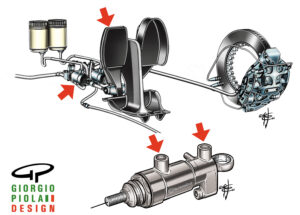

Will there be innovations at the level of the brake pumps as well?

“In 2026, everyone will redesign front and rear calipers, disc design, and they are also taking the opportunity to equip the car with slightly different-sized pumps. Here too, the regulations allow for a bit more freedom. The diameter difference between the front and rear pump in 2025 was 2 mm, while in 2026 it will increase to 3 mm, because the effort at the rear is expected to be lower than at the front, and so the difference between the two is managed with a greater diameter difference between the pumps.

Almost all teams now have a tandem pump, meaning a single pump with two chambers inside: one operating the front system and one operating the rear system. The rear system is controlled by the BBW (Brake-By-Wire), so in reality the rear pump almost never works except in the case of a BBV (Brake-By-Vehicle) failure. In that case, the driver can actually brake using the calipers; otherwise, rear pressure is always managed by the BBV.”

Drivers will continue to make the most of brake distribution. Below is the two-stage pump that regulates this device.

Will the 30 kg reduction in total car weight be a tough challenge for the braking systems as well?

“The concern is that, in the end, the cars will generally all be over the minimum weight, so the search for a lightweight solution is quite intense and relentless. Obviously, if you further subdivide a caliper, you might end up with a slightly heavier caliper, but one that provides other advantages in the design of the disc and the corner wheel, so it’s always a compromise. The target is to have a front system similar to, or slightly heavier than, what we had in 2025, while at the rear the goal is to significantly reduce both weight and size.”

When designing a new caliper, what is the synergy with the teams during the design phase?

“In most cases, the team arrives with fairly clear ideas about the corner wheel. The limits imposed are the shape of the upright, the installation in the car, the caliper’s installation angle, and its position relative to the axle, as well as the rim design, especially its inner part. This last factor defines the available space for the caliper.

There are precise limits set by the team, although it can happen that the team evaluates two different solutions because they are undecided from an aerodynamic standpoint about which position might be best, and so they also consider the impact on caliper design. The team may request a preliminary study to understand the advantages and disadvantages of the two solutions.

Once the caliper’s angle in the car is decided, it is designed to be bled in the car, with all the channels positioned correctly. The goal is to achieve the best weight-to-stiffness ratio, and then cooling features are added. Here too, the choice is subjective: each team has its own cooling strategy—some prefer pins, others prefer fins, others prefer holes or slightly worked surfaces on the caliper exterior.

These solutions somewhat conflict with the goal of minimizing weight, but they provide a real advantage in heat dissipation. So the team decides, based on CFD and photodynamic studies, whether it’s worth adding a few grams to the caliper body to ensure cooler zones and better overall cooling.”

Each team will have a new caliper developed in collaboration with Brembo, with customised features, particularly in the cooling systems: pins, fins, radiators, and holes.