THE REVOLUTION OF THE 98 SEASON

Even in the 1998 season, the FIA had carried out a real revolution—obviously not a complete leap into the unknown like the one planned for the season about to begin. At that time, the goal was not to start from scratch with a new engine formula, but rather to reduce performance and further improve safety by imposing heavy and radical changes across all other areas.

The objective focused mainly on three sectors: reducing the maximum width and therefore the track width, introducing grooved tires in place of slicks, and penalizing braking systems, along with major modifications aimed at improving safety.

The minimum internal dimensions of the front part of the chassis, in the area around the driver’s legs, were increased. This was a prompt response to the failure in that area during Olivier Panis’s dramatic accident in the Prost at the Canadian Grand Prix the previous year.

NARROWER ’98 SINGLE-SEATERS AND GROOVED TIRES.

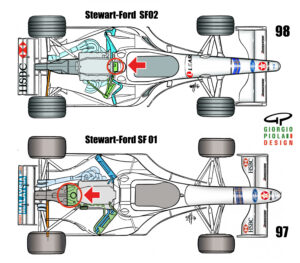

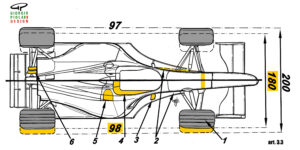

The two most visible changes cocern the 20 cm reduction in single-seaters width—actually greater than the current 10 cm reduction—and the introduction of grooved tires. In the illustration, a ’97 edition single-seater is compared at the top with the ’98 version at the bottom.

The maximum width of the single-seaters (art. 3.3) went from 200 cm to 180 cm; in effect, the track width was reduced and the wheels moved closer to the body. Shorter suspension arms are noticeable.

- Tires had to feature longitudinal grooves: three on the front and four on the rear.

- The minimum chassis width was increased in the area around the driver’s legs.

- The size of the rearview mirrors was increased: from 10 cm to 12 cm in width, with the height unchanged at 5 cm.

- Side protection around the driver’s head had to extend up to the height of the steering wheel.

- Fuel filler caps had to have a closing mechanism to prevent opening in the event of an accident.

- Exhaust outlets could not extend beyond the wheel axis in the outer 30 cm of the central zone.

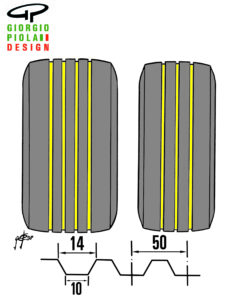

GROOVED TIRES

Dry tires (slicks until 97) must have longitudinal grooves: three on the front tires and four on the rear.

The width of these grooves must be 14 mm, with a depth of at least 2.5 mm. The distance between the centers of two grooves must be 50 mm. Measurements are taken with the tires inflated to 20 psi. Tires must always retain the grooves after use.

The Federation also imposed new tire dimensions: the maximum diameter is reduced from 660.4 mm to 660 mm, the maximum width from 381 mm to 380 mm, while the minimum width—which was previously undefined—is now 305 mm for the front and 365 mm for the rear. Rim diameter is reduced from 330.2 mm to 330 mm.

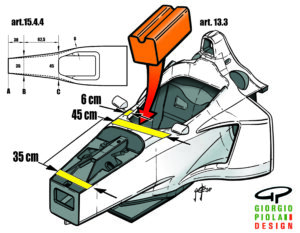

WIDER AND SAFER CHASSIS (art. 15.4.4)

For the 1998 season, the minimum dimensions for the front part of the chassis were increased, and the side walls were made straighter.

The minimum dimensions must be:

- 25 cm at point A (front bulkhead),

- 35 cm at point B, located 30 cm from A,

- 45 cm at point C, located 62.5 cm from B.

Additionally, the minimum thickness in the cockpit area must be 6 cm. The dimensions valid until ’97 are shown as dashed lines.

The protective material on the sides of the driver’s head must extend in a straight line up to the height of the steering wheel.

A very important restriction was imposed on the internal dimensions of the chassis in the pedal area (art. 13.3). It must be free of suspension components, covering an area of 900 cm², large enough to fit a wooden block of 30 cm per side, with a slight cutout at the top to allow the steering column to pass through. This solution ensures greater safety and facilitates the extraction of the driver in the event of an accident.

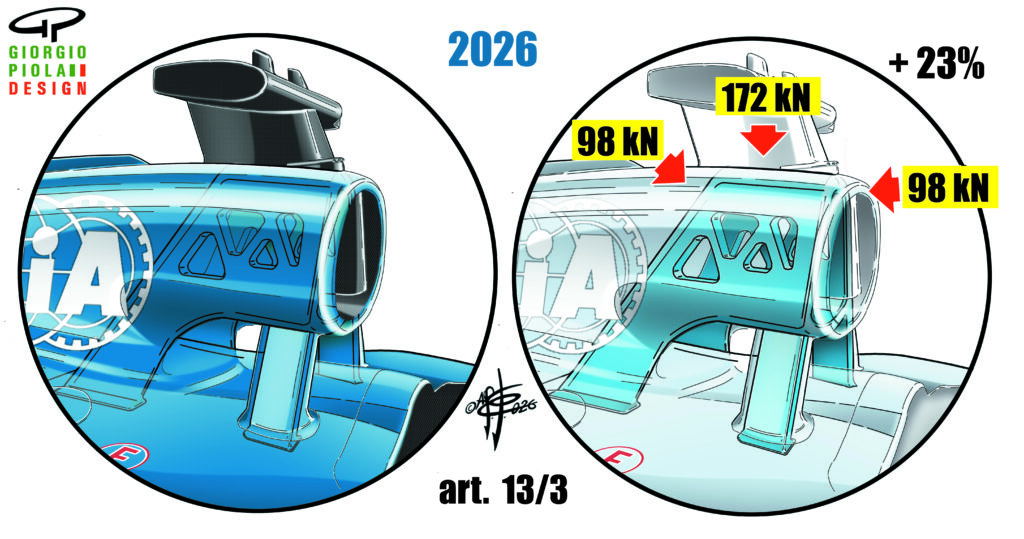

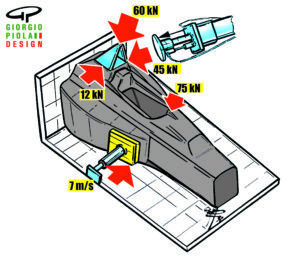

CRASH TEST ROLL BAR (art. 15.2.3/4)

The load requirements for the two safety roll bars protecting the dashboard area and behind the driver’s head were made more stringent.

The first roll bar had to withstand a vertical force of 75 kN; the second had to resist a load equivalent to 60 kN vertically, 12 kN laterally, and 45 kN longitudinally. Under load, the maximum allowed deflection was 100 mm.

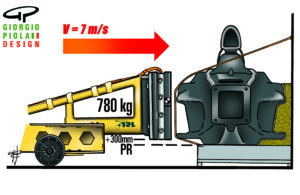

SIDE CRASH TEST (art. 15.4.5)

The speed of the side crash test was increased from 5 m/s to 7 m/s, with the chassis in running order and a weight of 780 kg.

Chassis must pass a significant number of tests to receive Federation approval; some of these tests must be performed on all units. Inspection is carried out by technical commissioners at the race tracks. Using a reader/scanner (produced by the German company Trovan), data are collected from microchips embedded in the chassis at three different points. Essentially, these microchips record the history of the chassis during the crash test evaluations.

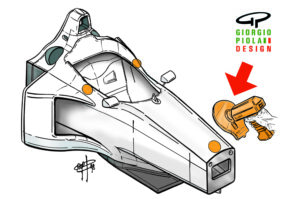

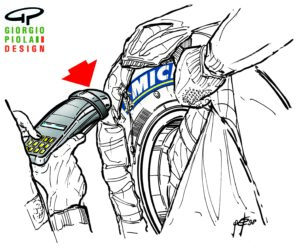

TIRE INSPECTION

Also in the 1998 season, the Federation introduced a further refinement regarding the inspection of the tires available to each team.

No more hard-to-read numbers—now a barcode can be scanned with a laser reader in just a few seconds.

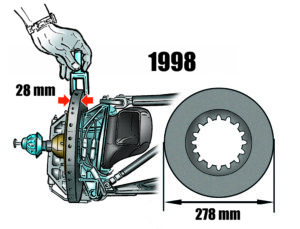

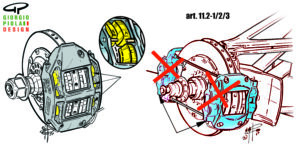

BRAKE RESTRICTIONS (art. 11.2.1/2/3)

To try to slow down the single-seaters and increase overtaking opportunities, the FIA significantly restricted braking systems for the 1998 season. These constraints have mostly been removed for the 2026 season.

Exotic materials such as beryllium were banned for the manufacture of calipers. The maximum allowable modulus of elasticity could not exceed 80 GPa. Only one caliper per disc and no more than one disc per wheel were permitted. Calipers could have no more than six pistons and no more than two brake pads. The maximum disc diameter was 278 mm, with a thickness of 28 mm. Cooling fluids were prohibited.

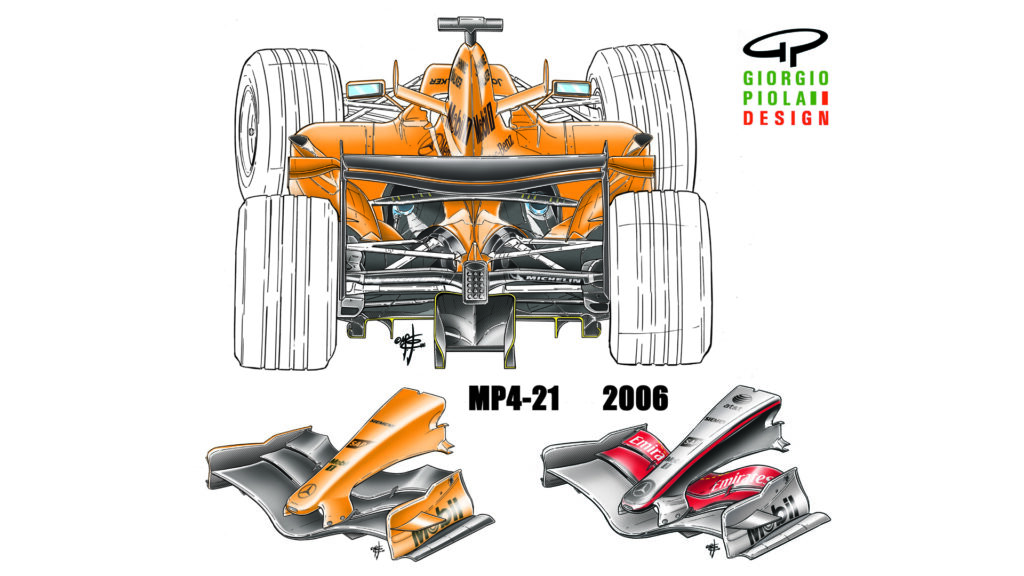

In 1997, braking systems had undergone significant development with new solutions and, above all, very stiff and lightweight materials. The new rules effectively abolished solutions such as Brembo’s 8-piston beryllium calipers, A+P’s dual calipers used exclusively by Stewart on the front axle, and four pads per disc. All these restrictions were eventually bypassed, except for the rule limiting calipers to one per disc.

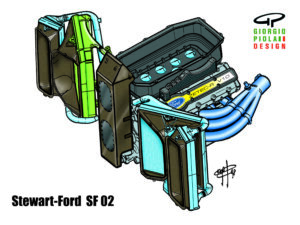

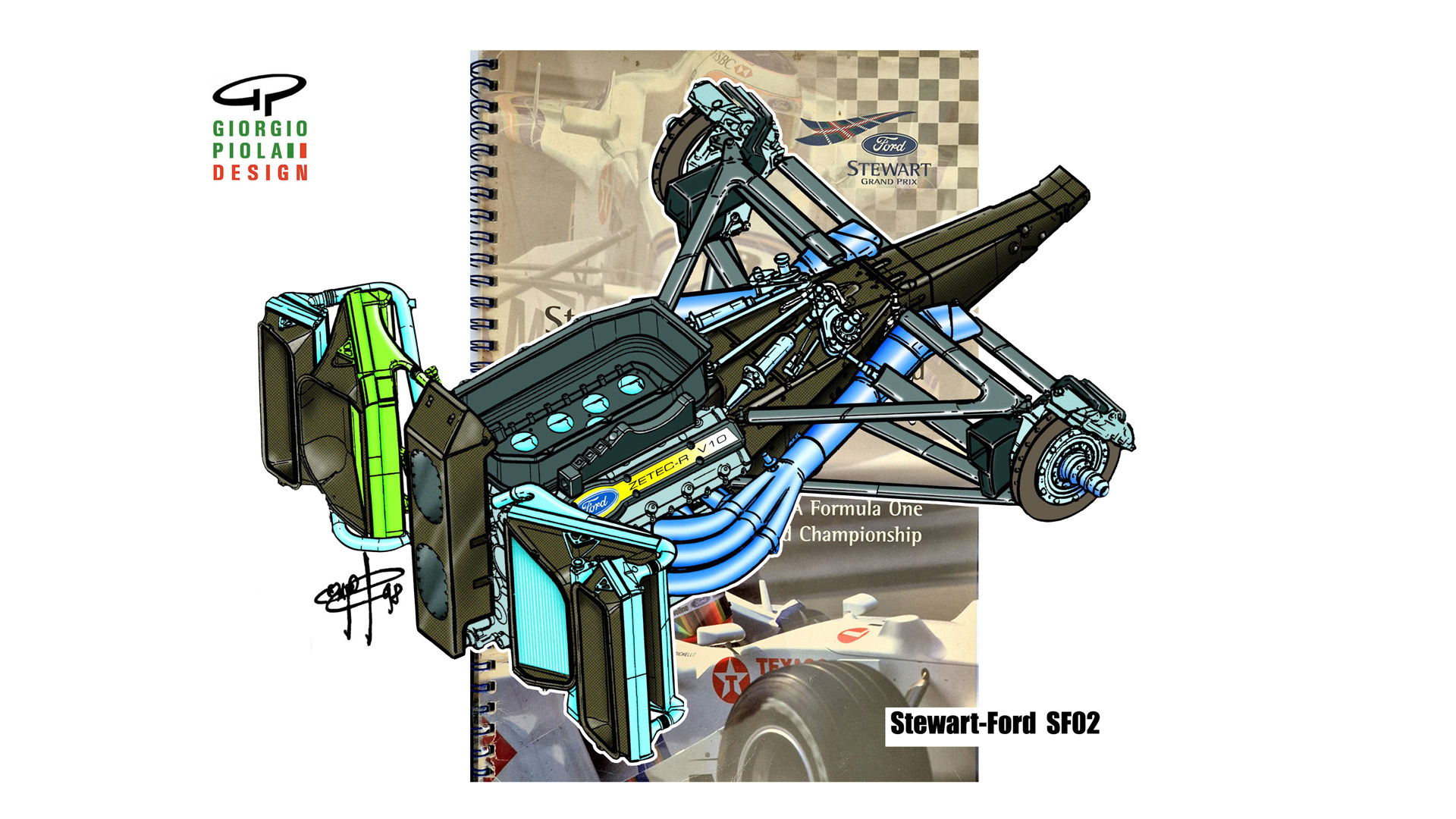

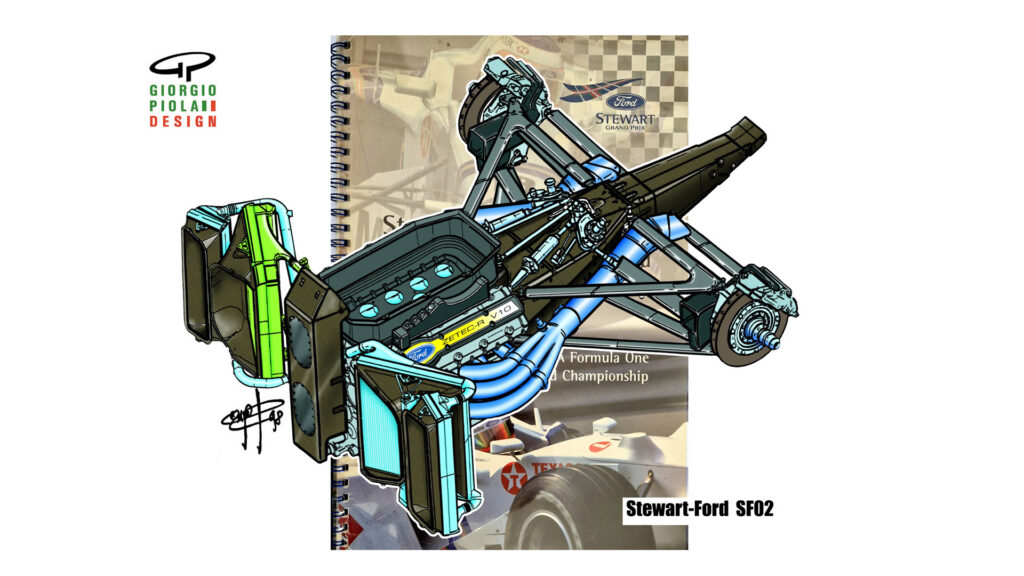

As always happens when regulations change radically, the 1998 season also saw the birth of new solutions. The most unusual aspect is that as many as three teams (Stewart, Arrows, and Prost) simultaneously introduced an unprecedented position for the oil tank between the monocoque and the engine, close to the car’s center of gravity, whereas until then it had been placed farther away between the engine and the gearbox.

Also new was the gearbox solution, with the casing made of carbon fiber for the first time, both on Alan Jenkins’s Stewart and on John Barnard’s Arrows. This represented a complete reversal of the layout, which from then on became standard across all Formula 1 cars and has remained unchanged to this day.

It is a solution I particularly enjoy talking about because in November 1997 Alan Jenkins asked me to produce the drawings for the press kit to be distributed instead of the traditional presentation of the actual car. Not only that: at the factory he provided me with the CAD drawings from which I then created the illustrative plates. Another detail is that that year marked my debut with the computer for my freehand drawings.